T-RICH

Tampa Regional Intermodal Carbon Hub

Aptamus, through its parent company OSG, was awarded a $320,000 grant from the U.S. Department of Energy (DOE) in 2024 to conduct a pre-FEED study to assess the feasibility of a CO2 hub in the Tampa Bay region. The Tampa Regional Intermodal Carbon Hub (“T-RICH”) is a proposed comprehensive intermodal transportation hub for captured CO2 on the west coast of Florida sited at Port Tampa Bay. T-RICH is intended to be the principal gateway for intermediate storage of CO2 captured from emitters across the State of Florida. The hub will receive, store, and process no less than 2,000,000 metric tons (mt) of CO2 per year for permanent sequestration on- and offshore in the Gulf of Mexico region as such sites receive final Class VI permits. The potential future throughput of the plant is as much as 8,000,000 mt per year. The Tampa Bay region is home to a high concentration of power generating facilities and large industrial CO2 emitters. Port Tampa Bay has identified a 15 acre parcel with access to an existing deep-water berth. The deep-water berth is critical for the efficient transport of outbound CO2 on a ship, which will minimize the cost of transport of the CO2 thereby maximizing project viability. An evaluation will include all necessary modifications for direct, unimpeded, safe access for delivery of CO2 from emitters throughout the region and the state on ship, rail, truck, and pipeline transportation pathways to the storage tanks at the hub site. The project will also evaluate system requirements for direct discharge of CO2 captured onboard ships which call at Port Tampa Bay into the hub tanks. Development of this hub would involve installation of storage tanks and related liquefaction, temperature and pressure equipment at Port Tampa Bay in the United States.

UPDATE NOVEMBER 2025: Aptamus completed its pre-FEED study in September 2025. The 240-page report, written in conjunction with engineering consultancy Entr (part of Aker Solutions) with additional input by Port Tampa Bay’s engineering staff, summarizes all of the top-level engineering, regulatory and safety considerations that must be included in an evaluation of such a complex industrial plant. Read the full report here. We are building on this work in the performance of the FEED (front end engineering & design) study which includes not only T-RICH but the discharge terminal in Louisiana and the LCO2 vessel which transports LCO2 between them. That study is expected to be completed by the end of 2026. See here for more details.

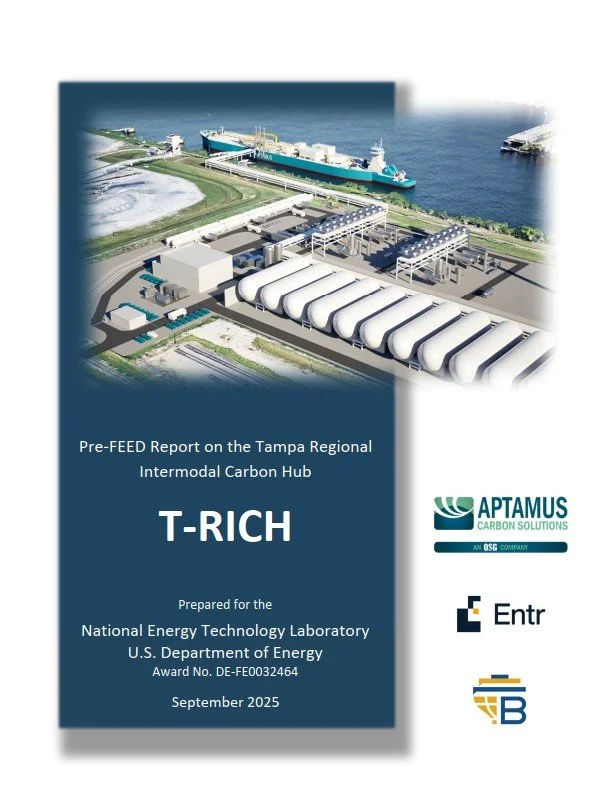

3D rendering by Aker Solutions Canada

FEATURES AT A GLANCE:

Total throughput 2,000,000 tons per year.

Two 50% capacity liquefaction trains

30,000 m3 of LCO2 storage.

CO2 enters via pipeline, rail or truck.

CO2 exits on dedicated marine vessels.

Approximately 10 acres of land area.